Departmental Shared Facilities

The Mechanical Engineering Department offers a list of shared laboratory equipment for UGC funded students or staffs, to support their research in engineering, material science, and various other disciplines. Under user-pay principle, the users or their supervisors should allocate budget for using the equipment. The detailed charging scheme can be found in https://mech.hku.hk/mech_facility_charging/. To apply for usage right(s), please visit the Moodle page: https://mech.hku.hk/admin_n_safety, or contact the laboratory technician, Mr Patrick Ng (email: patckng@hku.hk), for assistance.

Zeiss Sigma 300 SEM

The Sigma 300 SEM, from Zeiss, is a field emission scanning electron microscope. It offers ultra-high resolution for both SE to image surface information and BSE to present compositional information in the high vacuum mode. In addition, EBSD and EDS imaging modes are available to obtain crystal orientation and chemical composition information of samples. A variety of in-situ experiments can be performed during imaging, including tensile tests and nano-indentation experiments.

Detectors:

- SE2 and InLens – Secondary Electron Detectors

- BSD – Backscatter Electron Detector

- EBSD Aztec Symmetry NANOANALYSIS WITH Fast & High Sensitive CMOS Camera, Maximum Indexing rate 3000HZ

- Energy Dispersive Spectroscopy (EDS) detector

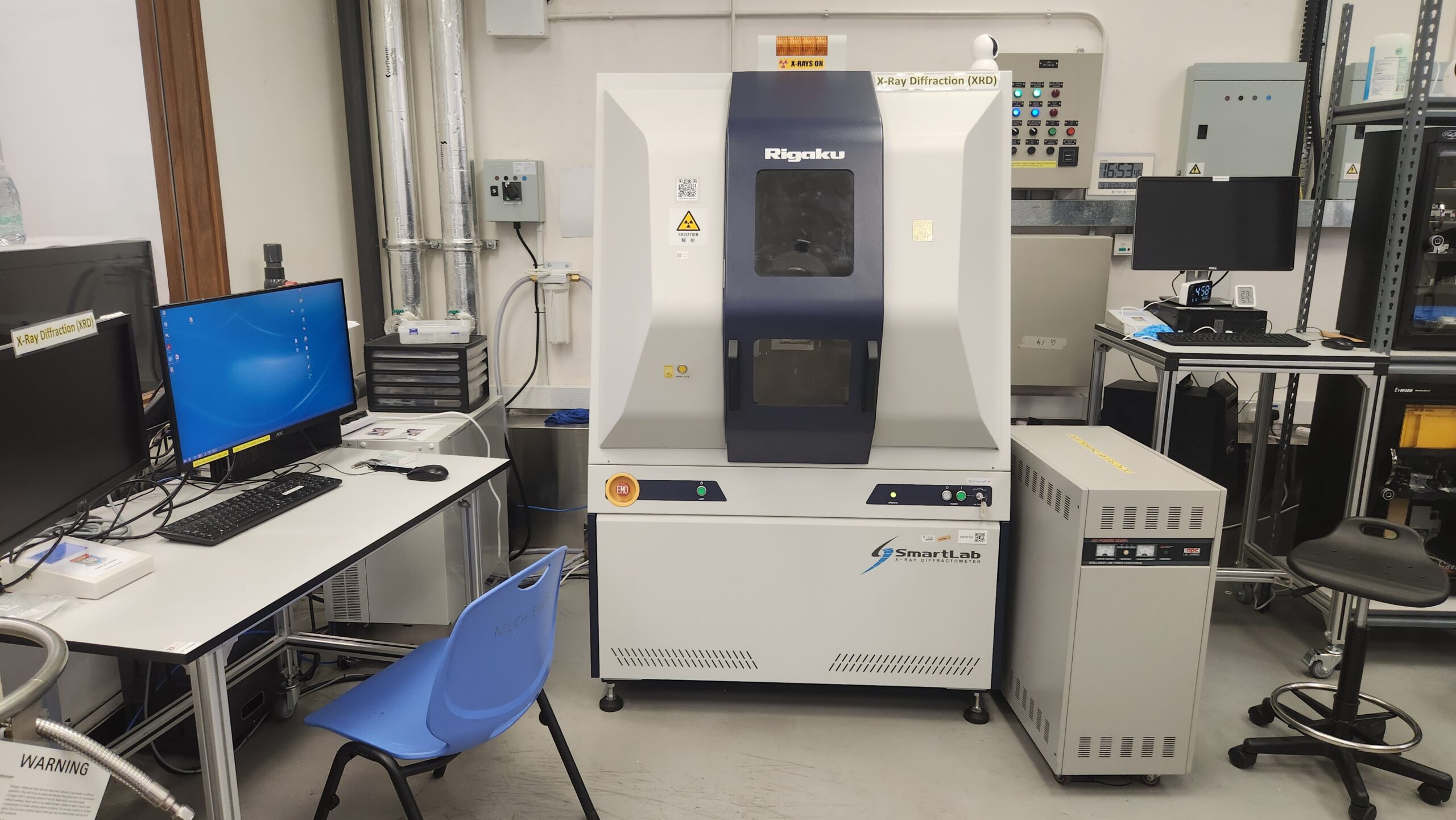

Rigaku SmartLab 9kW X-ray diffractometer

XRD is a non-destructive technique to obtain the structure of materials at atomic or molecular level. The diffraction pattern provides information such as atomic structures, lattice parameter and chemical bonds. Applications of XRD include phase determination, crystallography, pharmaceutical research, semiconductor defects, strain, stress analysis, etc. Materials studies vary from salts, metals, minerals, semiconductors thin films, organic, inorganic, nanomaterials, biological molecules, etc.

Specifications / Applications:

- 9 kW high power X-ray generator

- Micro-area X-ray diffraction measurements (X-ray spot size down to 300um diameter)

- Automatic 8 position powder sample changer with spinner

- Full automated alignment under computer control.

- The system incorporates a high resolution θ/θ closed loop goniometer drive system, cross beam optics (CBO), an in-plane scattering arm, and an optional 9.0 kW rotating anode generator.

- Focusing and parallel beam geometries without reconfiguration.

- SAXS capabilities.

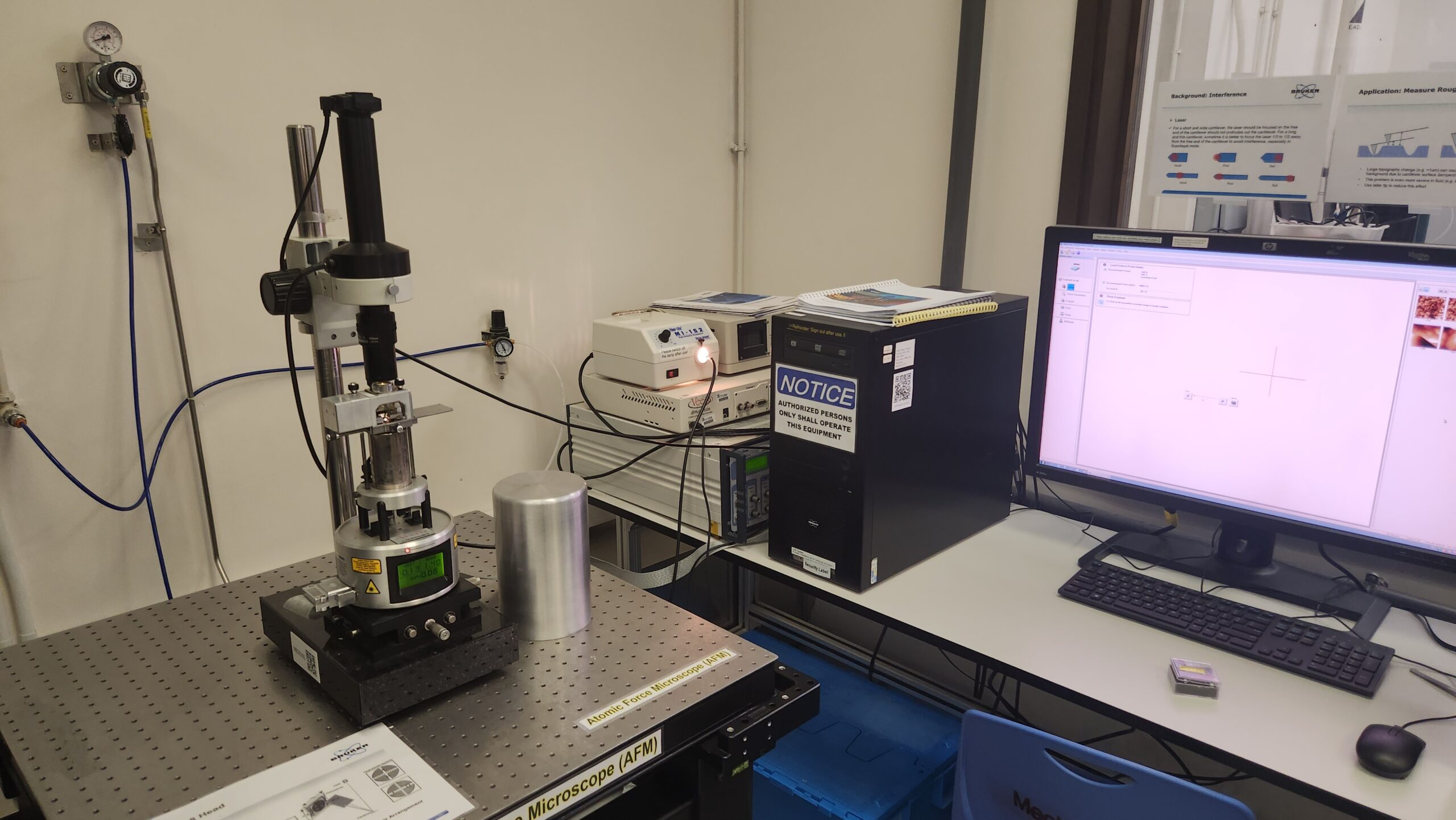

Bruker MultiMode 8

The Bruker MultiMode 8 AFM provides nano-meter surface topography imaging and pico-Newtown surface force measurement in both air and liquids. Bruker’s exclusive ScanAsyst mode offers automatic image optimization for faster, more consistent results. It will continuously adjust scan rate, setpoint and gains to obtain the highest quality image. Imaging in fluid has never been easier. There’s no need for cantilever tuning and ScanAsyst continuously monitors the tip-sample interaction force, thereby eliminating setpoint drift. PeakForce QNM enables direct mapping of nanomechanical properties, including elastic modulus, adhesion and dissipation, at high resolution and normal scan rates. The data channels are quantitative and unambiguous, unlike conventional phase imaging and some competing multi-frequency techniques.

Specifications / Applications:

- Contact, Tapping, and ScanAsyst imaging modes

- Normal and lateral forces measurement

- AFM resolution: < 5 nm

- No additional sample treatment needed

- Chemical-electric measurement module

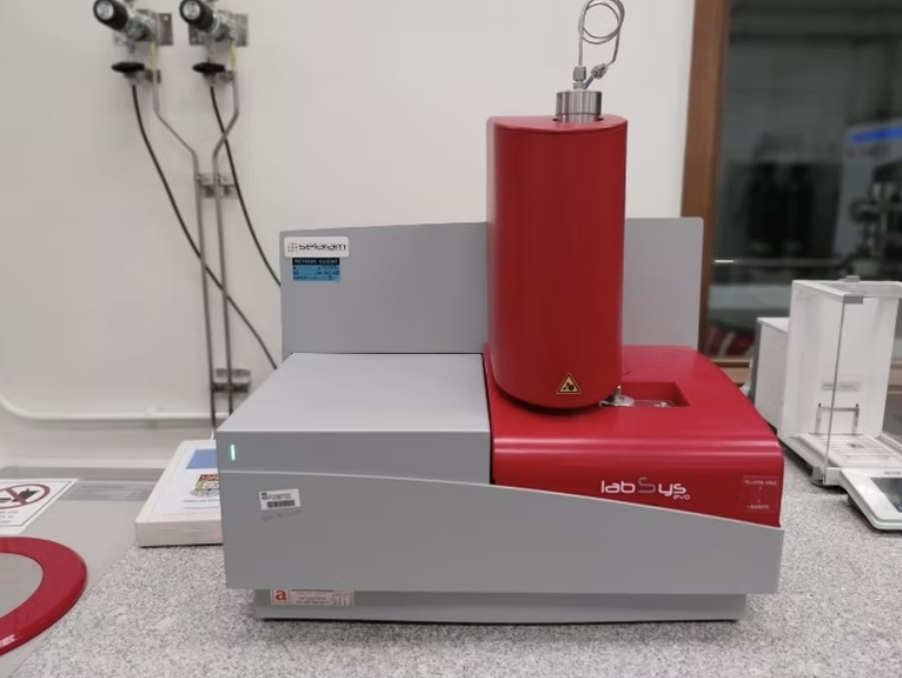

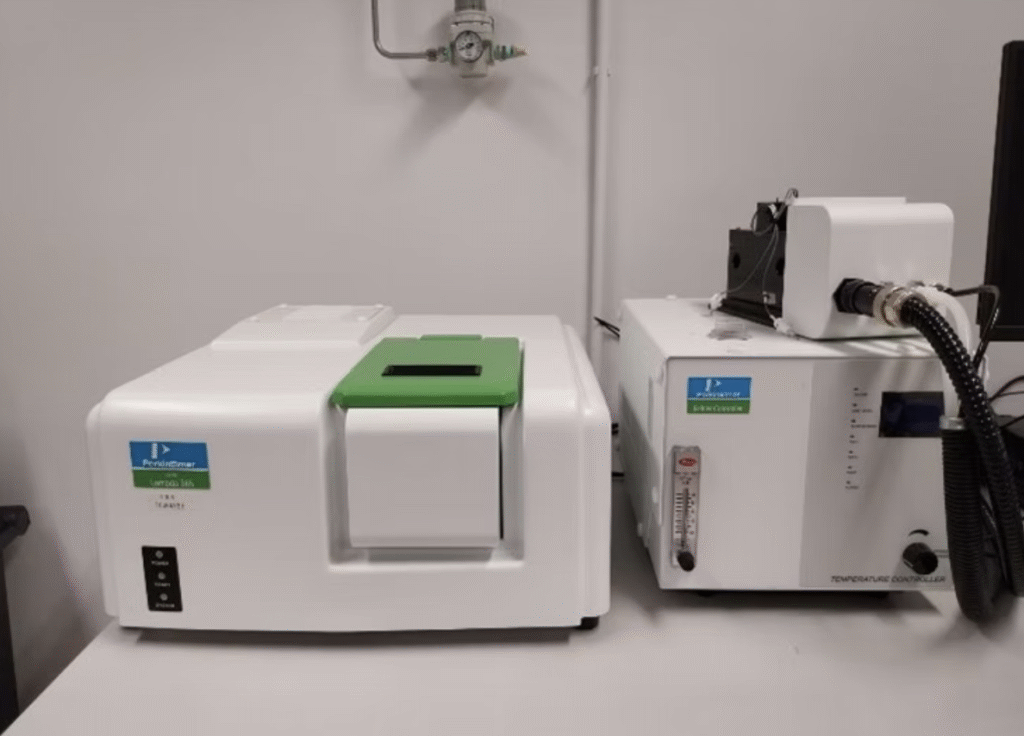

Setaram Labsys Evo

Labsys evo has a wide range of applications for DSC/DTA, TGA, simultaneous TGA-DSC/DTA, Cp measurements. Various fields of application are possible including polymers and plastics, advanced materials, pharmaceutical compounds, inorganic substances, thermodynamics (Specific Heat Capacity Cp precision within 2 %), energy, etc.

Its wide temperature range is: from 25 ° C to 1600 ° C

Gas type: UHP Argon, UHP Nitrogen

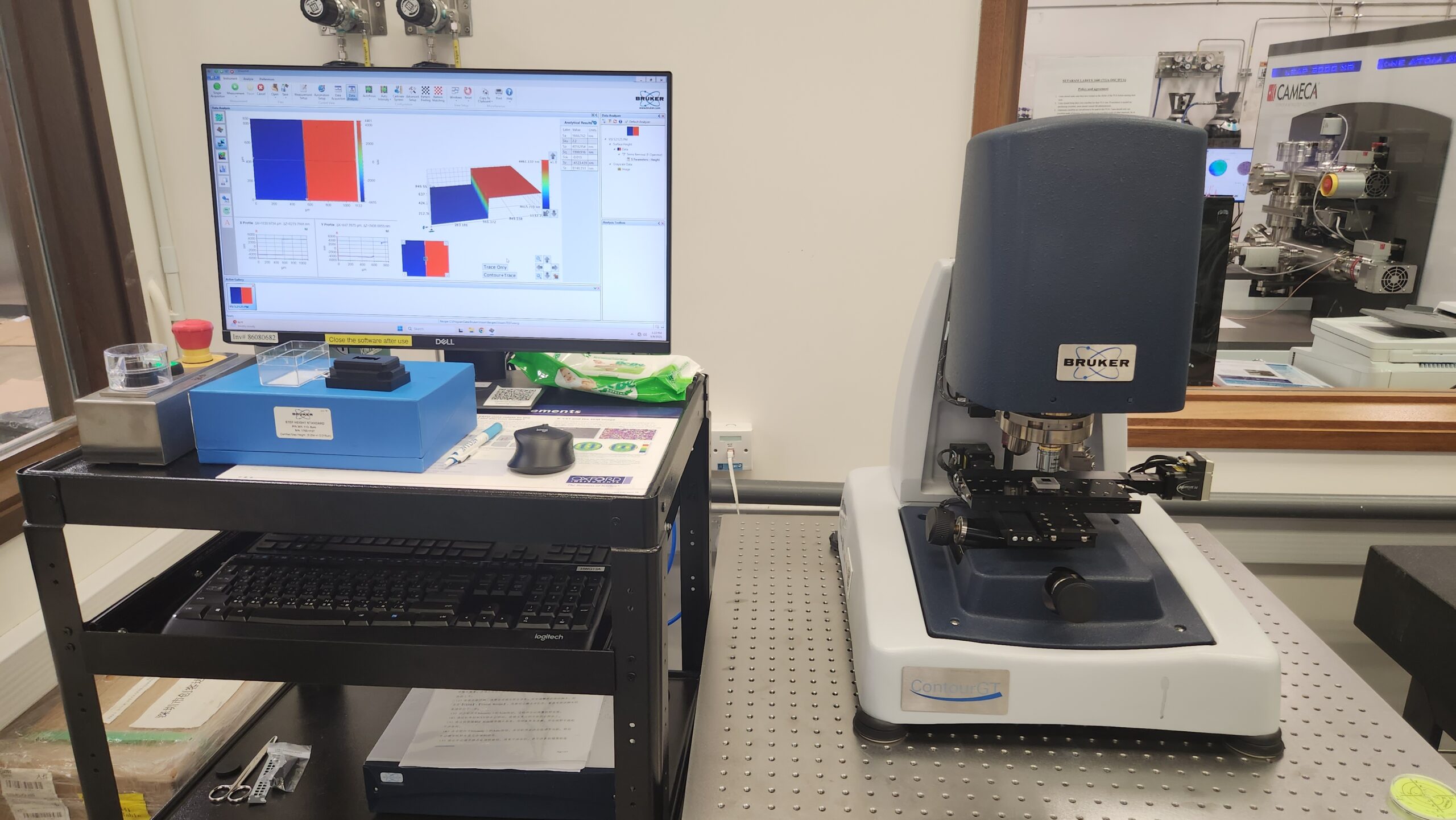

Bruker Contour GT-K Automated System

The Bruker Contour GT-K Automated System utilizes white light interferometry to aid researchers in 3D non-contact surface metrology studies. It divides a beam of light from a single source into two, directs one of them onto the sample surface, and then recombines the beams to create an interference pattern. By measuring the path difference between the two beams, the sample surface profile can be obtained with high degree of vertical resolution

Specifications / Applications:

PSI, VSI, VXI modes

- Stitching function available

- Accurate and repeatable throughout the 10mm scan range

- Patented dual LED illumination

- 5X and 10X interferometric objectives

- 5X, 10X and 20X interferometric objectives

- Thick film measurement capability

- AcuityXR enhanced resolution measurement mode (including HDVSI)

LAMBDA 365

The LAMBDA™ 365 delivers state-of-the-art UV-Vis performance that meets the needs of pharmaceuticals, analytic chemists, geneticists, and manufacturing QA/QC analysts everywhere.

The system delivers a variable spectral bandwidth capability from 0.5 nm to 20 nm, the operation range is between 190-1100 nm, to meet your application needs. It can accommodate a wide range of accessories, including multicell changers, solid sample accessories for transmission, reflectance, and a range of cuvette holders to meet your sampling requirements.

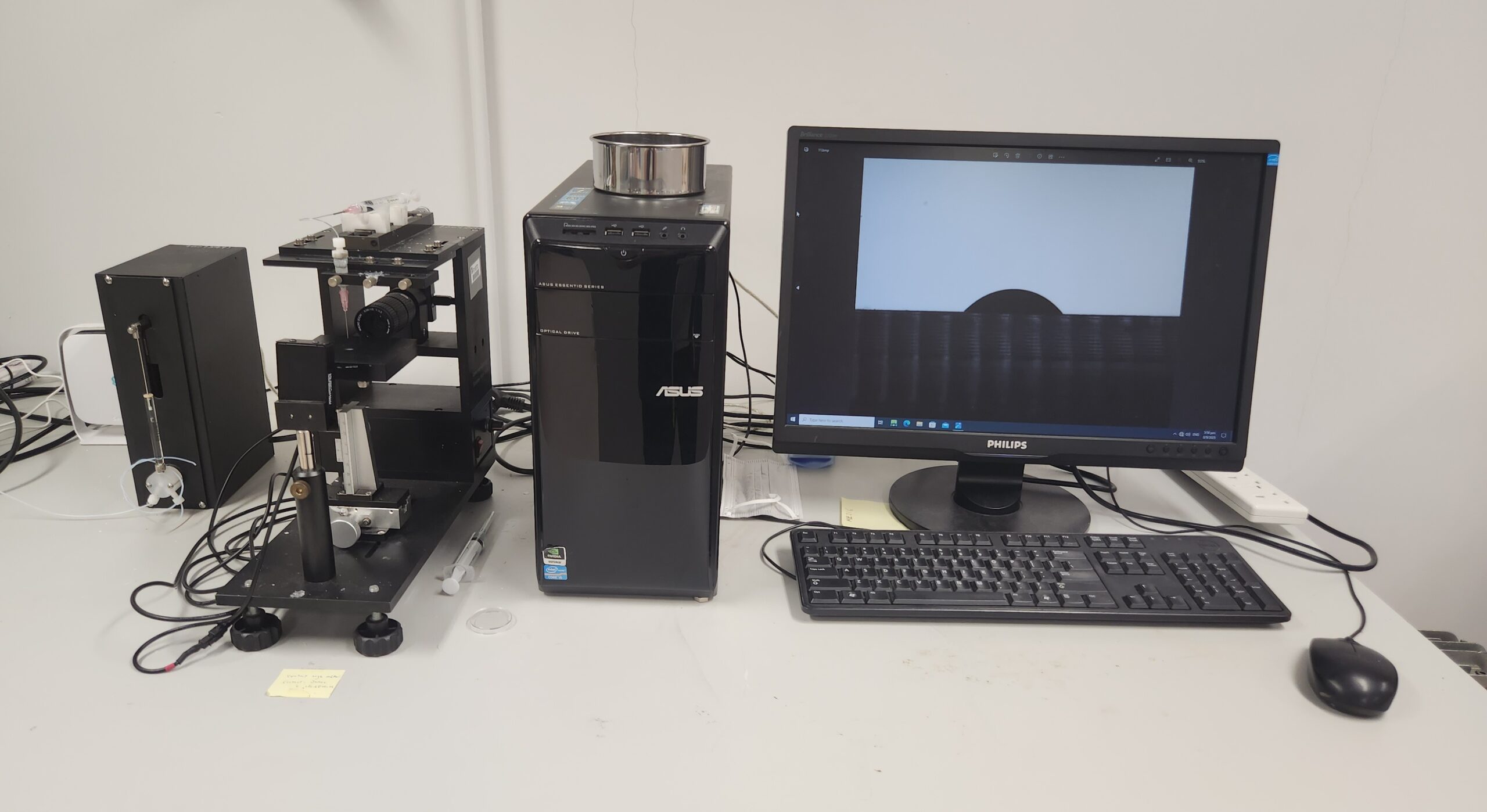

Sindatek Model 100SB

The Model 100SB consists of the basic hardware with the following technical features:

- Basic platform with needle holder and syringe support

- Homogeneous LED backlighting electronics with continuously adjustable intensity

- Measuring stage, adjustable in three axis for the accurate sample positioning

- Adjustable tilt optics

- Fixed lens with optional high-performance lens with an integrated continuous fine focus

- High resolution 1280 x 1024 USB 2.0 camera; optional 60 fps speed camera

- Manual dosing unit with fine 1.0 ul adjustable syringe

Integral X-Y-Z fine adjustable needle holder

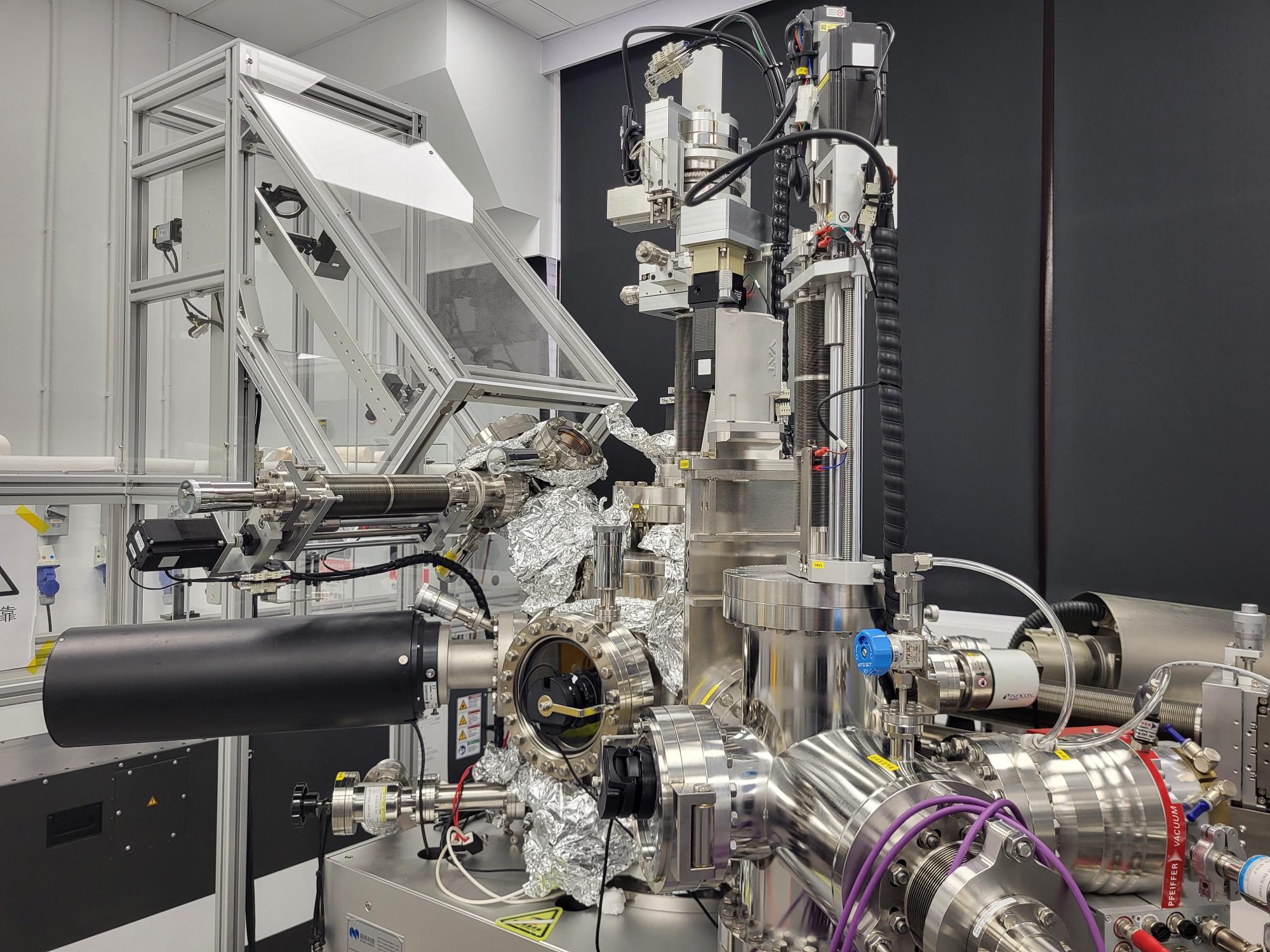

Cameca LEAP 6000 XR

Atom Probe Tomography (APT or 3D Atom Probe) is the only material analysis technique offering extensive capabilities for both 3D imaging and chemical composition measurements at the atomic scale (around 0.1-0.3nm resolution in

depth and 0.3-0.5nm laterally). Since its early developments, Atom Probe Tomography has contributed to major advances in materials science.

The sample is prepared in the form of a very sharp tip. The cooled tip is biased at high DC voltage (3-15 kV). The very small radius of the tip and the High Voltage induce a very high electrostatic field (tens V/nm) at the tip surface, just below the point of atom evaporation. Under laser or HV pulsing, one or more atoms are evaporated from the surface, by field effect (near 100% ionization), and projected onto a Position Sensitive Detector (PSD) with a very high detection efficiency. Ion efficiencies are as high as 80%, the highest analytical efficiency of any 3D microscopy.

Cameca LEAP 6000 XR APT inherits key features from previous APT generations, adding deep UV laser pulsing to the proven local electrode design to deliver higher yield and data quality. Through compatibility with the microtip array and a redesigned optical system, the LEAP 6000 XR provides enhanced ease of use and the potential for fully automated operation.

MNT-S100Oz-L4 Atomic Layer Deposition

- Deposition of high-k dielectric materials: HfO₂ and Al₂O₃

- Precise thickness control: 10–30 nm

- Superior film uniformity across substrates

- Suitable for semiconductor device fabrication

- Applicable in advanced material and nanotechnology research

Pulsed Laser Deposition

- Femtosecond Laser Transient Absorption Spectroscopy System

- Components:

- PH2-20W: High-power femtosecond laser

- ORPHEUS-HP: Optical parametric amplifier (OPA)

- ORPHEUS-HP-SH: Second harmonic generation module

- HELIOS VIS: Transient absorption spectroscopy system

- Microscope (SGL SPOT+REFLECTION ADDON)

- Applications:

- Development of ultra-high dielectric constant insulators

- High-quality, large-area film deposition for electronics

- Materials science, nanotechnology, and semiconductor research

- Fabrication of high-k dielectric materials (capacitors, transistors)

Real-time monitoring and analysis of film properties

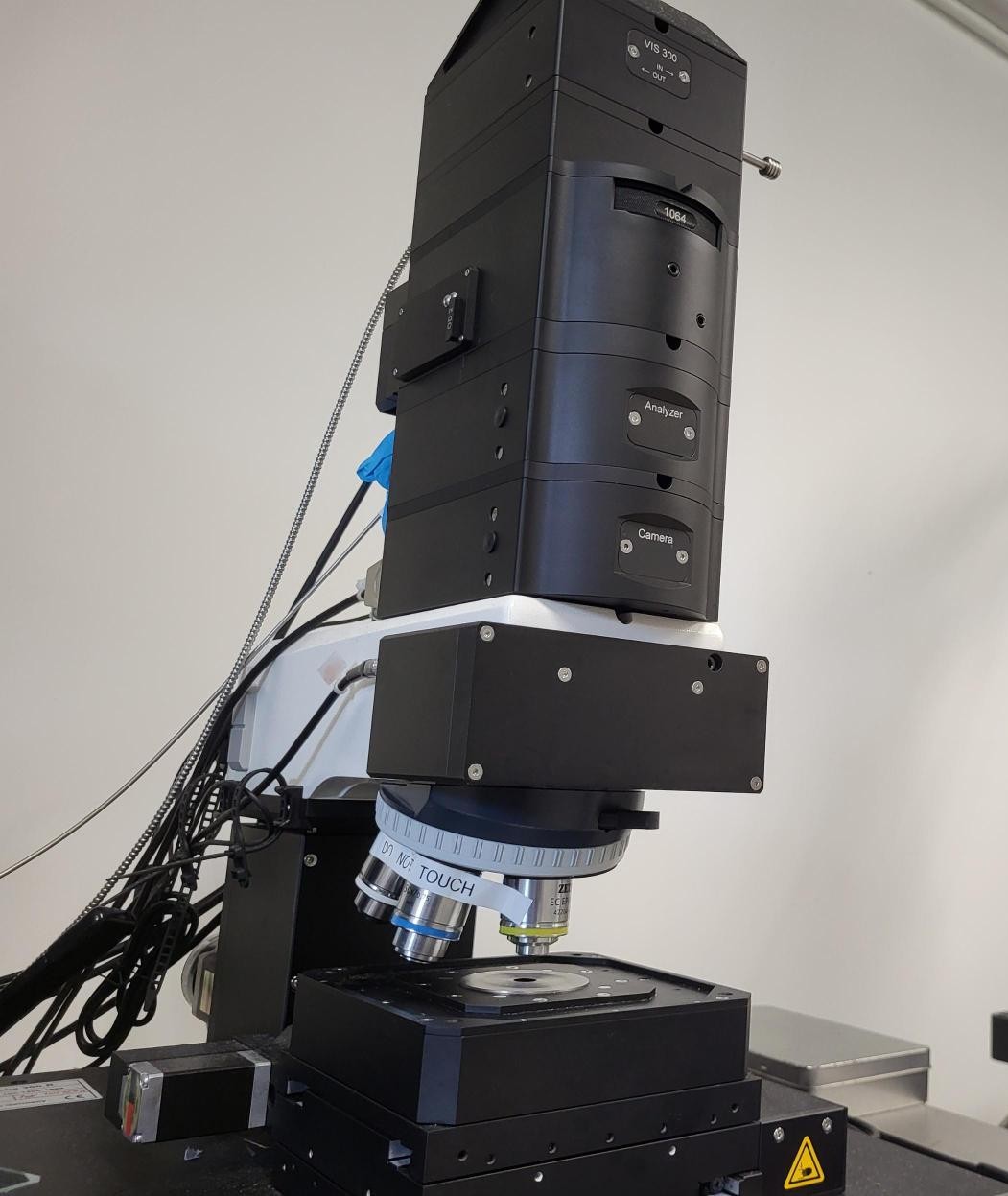

Confocal Raman Spectroscopy -

High Resolution Raman and PL Mapping

- High-resolution confocal Raman and PL mapping capabilities

- Integrated WITec multiwavelength laser coupler for versatile excitation options

- Microscope base with high stability and precision control

- Temperature control system for accurate sample environment management

- Ideal for detailed chemical and structural analysis of materials

- Applications in materials science, chemistry, nanotechnology, and more

Enables the study of material properties, phase identification, and stress/strain analysis